Hot search keywords:

Position:Home>Automatic> GT-1500AP automatic burner

Click:316Time:2017.05.10source: www.ic-test.cn

◆ Mainly for small-capacity multi-species IC burning, can reduce costs, there is a demand situation

Expanded to models GT2-2000AP

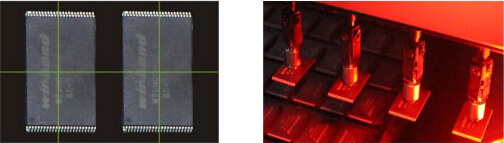

◆ Equipped with 2 nozzle, and the future can be extended to upgrade 4 nozzle, the maximum capacity of 1500 UPH

◆ Can be equipped with 6 groups of burning core, and can be expanded 12 groups, the independent operation of the core, which can burn 24PCS

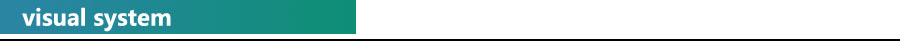

◆ High-precision hardware, with removable CCD, any part of the material to take the image travel to minimize

◆ Zero bad, zero-disc changer, zero downtime

The new generation of GT-400AP models burn the core

◆ Support MCU / MPU, SPI Memory, NOR / NAND Flash, EEPROM, EMMC, Emcp and other IC

◆ EMMC device read and write speeds of up to 100MBytes / sec (beyond the current EMMC limit speed 5 times)

◆ Can be equipped with 6 groups of core and can be expanded 6 groups, the core group of independent operation

◆ Independent pin drive circuit, multiple burn each other does not interfere with the burning yield zero bad

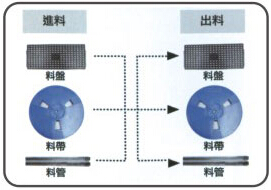

◆ I / O support: Roll out, Roll into the disc, Roll out of the tube

Disk into the disk out,Plate rolled out,Disk into the tube out

Tube into the tube out,Tube into the volume,Tube into the disk out

The industry's first use of Tray dual track design, zero change disk time and authorized access to invention patents

◆  Accurate structural design, action difficulty, and perfect system parameters, mobile positioning, to ensure high-speed operation under the accuracy and accuracy, minimize travel, maximize production capacity

Accurate structural design, action difficulty, and perfect system parameters, mobile positioning, to ensure high-speed operation under the accuracy and accuracy, minimize travel, maximize production capacity

◆ Degree of analysis:X axis:±0.01mm,Y axis:±0.01mm,Z axis:±0.01mm

◆ Rotation axis resolution:⊙=0.15゜

◆ Take the accuracy:±0.01mm

◆  Image capturing means:Fixed CCD:1280×966 pixels.

Image capturing means:Fixed CCD:1280×966 pixels.

◆ Imaging caliber:30mm×30mm

◆ Image accuracy:±0.01mm

◆ Image processing speed:~0.02sec/unit

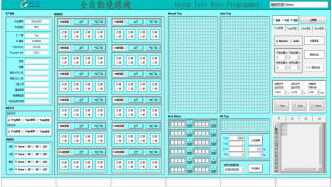

◆ The industry's first intelligent system, abnormal automatic identification off, zero stop processing

◆ Burn the project file, image settings, the location of a set of complete storage, transfer directly from the line

◆ Simplified / English interface, the user interface is simple

Number of burns | Burn the foot | 24PCS |

Burning speed | Burn production capacity | UPH:1500PCS/H |

Suction nozzle | 2 Suction nozzle | |

Mobile system | Transmission system | Import high-precision ball screw and linear slide |

Drive System | Import high-precision servo motor | |

Place precision | ±0.01mm | |

GPS | X/Y/Z Mobile system | X/Y/Z axis:±0.01mm:U axis:0.15° |

CCD | 1.3 megapixels, the next CCD moves with the Y axis | |

Affect the processing speed | 0.02S/device | |

Access device | Plate mounted(Tray) | Double track Tray, zero change disk time, can also place OK disk, to be burned 20 each |

Tray RBI | Tray RBI, support numbers, English letters | |

band Installed(Tape) | 8-32MM material gun, which can carry two sets of guns at the same time | |

Automatic with equipment out of material, 8-44mm adjustable, automatic RBI, support RBI, digital | ||

Tube Installed(Tube) | Choose 4-8 tube | |

other | NG disk | |

Change time | Change line | Modular operation, intelligent software call |

Burn logo | Identify the way | Equipped with ink print module / laser logo (optional) |

Burn quality | Throwing rate | 0.03% |

Success rate | 99.97% | |

Burn information record | Automatic memory | |

Burn module | Burn count | Automatic memory |

Module mode | Separate plug-in single-phase | |

Control System | power supply | 220~240V Simplex/50-60 Hz |

Power consumption | 2.5KW(Rated maximum power) | |

Gas source | 0.6 MPa,45L/min | |

Machine size(W*D*H) | W1000 mm D1410 mm H1550 mm |